This training course qualifies the trainee to design geometric shapes for forming metals of all kinds and qualifies them to operate machines with digital control (CNC) and acquire the skills of executing geometric shapes. Which helps him to accurately implement the required technical and engineering parts.

The course is divided into:

- Engineering programming, KELLER technology programming, SINUMERIK 810D programming.

- Explain how to implement programs on the machine.

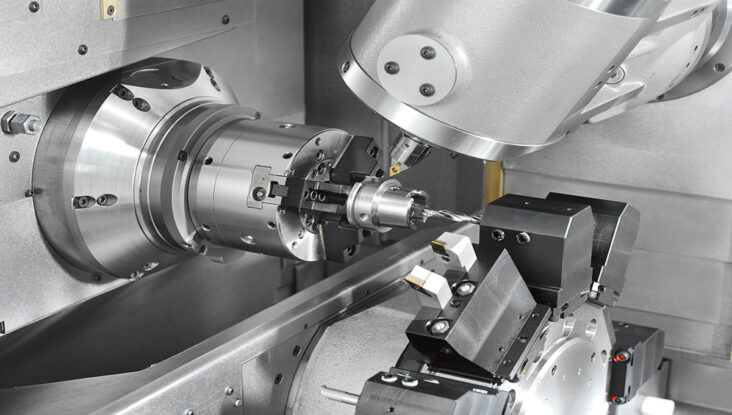

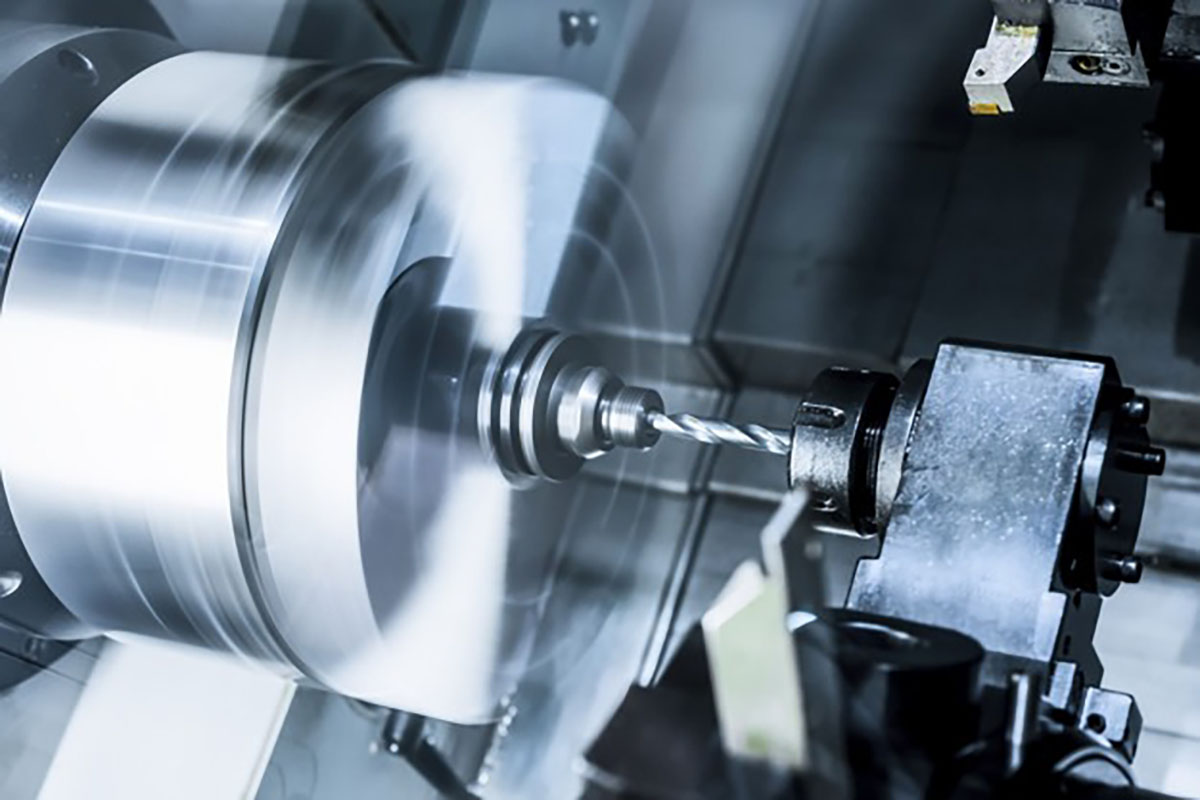

- A detailed explanation of the CNC machine EMCO TURN 155 with the implementation of the first lathe exercise on the machine.

- Programming and forming conical types with different shapes of external and internal lathing, external and internal stripped cone with external and internal threads, with the installation of parts together.

- An explanation of the types of TOOLS CNC machine and technological programming G54, G92, G96, G97, M3, M4, M8, M9, Feed, Speed Tool no. M30

- Explanation of thread cycle schedule with practical application.

- Learn to unzip the tools and reset them again on the machine to ensure that the student understands everything that has been done on the machine.

- Explanation of G40/G41/G42 and Work cycles, external and internal programming and drilling (drilling)

- 72 hours on 24 days

- Theoretical from 6 to 9 hours

- Egyptian nationality

- Graduate (Diploma – Institute – College)

- Proficient computer skills

- Pass the technical drawing test.

- Age up to 35 years

- Determine the status of the army for male candidates

- Seriousness and commitment

- Passing the personal interview